Electric Actuator Angular Stroke LMT Series

- category :Electric actuator

- email :vsdeme@vsdeme.com

- phone :+86-0578-2927663

LMT series electric actuators produced by lmtork are used to control 0 °~ ninety ° Rotary valves and other similar products, such as butterfly valve, flapper valve, plug valve, shutter valve, are widely used in petroleum, chemical industry, water treatment, shipping, paper making, power station, heating, building automation and other industries. With AC380V / 220V / 110V as driving power, switching signal (active and passive) and 4-20mA current signal as control signal, the valve can move to the required position, and the maximum output torque can reach 2000N · M.

Performance characteristics

1、 Overview of electric actuator products

LMT series produced by lmtork is a high-end intelligent angular stroke electric actuator, which is used to control 0 °~ ninety ° Rotary valves and other similar products, such as ball valve, damper, butterfly valve, flapper valve, plug valve, shutter valve, etc., are widely used in petroleum, chemical industry, water treatment, shipping, paper making, power station, heat supply, building automation and other industries.

The power supply uses AC380V / 220V / 110V (non-standard customized) as the driving power, switching signal (active and passive) and 4-20mA current signal as the control signal to make the valve move to the required position and realize its automatic control. The maximum output torque reaches 2000N · M.

2、 Performance characteristics of electric actuator

2.1 shell

The shell is made of hard aluminum alloy, anodized and coated with polyester powder, with strong corrosion resistance and protection grade of IP67. IP68 and B flameproof type are available for selection (please specify when ordering).

2.2 motor

Totally enclosed squirrel cage motor is adopted, which has the characteristics of small volume, large torque and small inertia force. The insulation grade of the motor is f and the built-in overheat protector can prevent the motor from being damaged by overheat.

2.3 manual structure

The design of handwheel ensures safety, reliability, labor saving and small volume. When the power is not available, pull the clutch handle for manual operation. When the power is on, the clutch will reset automatically.

2.4 dryer (optional)

It is used to control the temperature, prevent moisture condensation inside the actuator due to temperature and weather changes, and keep the internal electrical components dry.

2.5 valve position control

Realize the effective combination of mechanical counter and absolute value encoder, the valve position control is more accurate and reliable.

2.6 torque process control

Can provide overload protection, in the valve jam, foreign matter, automatically disconnect the motor power supply, more effective protection of the valve and electric actuator from damage.

2.7 simple debugging

The infrared setter can be used for simple, safe and fast non-invasive adjustment. The lmtork setter can be used to enter and adjust the actuator settings, such as torque value, limit, control and display functions. Lmtork provides a unique setter, which can set the actuator non invasively.

2.8 phase sequence self correction and open phase protection

The rotation direction of the actuator can be set freely, and the phase sequence of the power supply can be corrected automatically. The phase sequence of the power supply does not need to be considered in wiring. It also has the protection function of power supply phase loss and output phase loss.

2.9 signal free configuration and self diagnosis

There are 8 output contacts in total, 4 contact signals for users to choose, each signal can be defined freely, and the other 4 contact signals cannot be defined freely. Powerful fault self diagnosis function, convenient for users to deal with faults in time and quickly, and master the operation status of equipment.

2.10 bus technology

There are modbus, PROFIBUS and other bus communication modules.

2.11 installation

The bottom mounting size meets the international standard of ISO5211, the drive shaft sleeve can be removed and processed according to the needs, with strong adaptability. It can be installed vertically or horizontally.

2.12 lines

The control circuit meets the standard of single-phase or three-phase power supply, the circuit layout is compact and reasonable, and the terminal can effectively meet the requirements of various additional functions( It can be processed separately according to customers' requirements.)

2.13 split control

The control unit of the actuator can be installed separately from the mechanical parts to solve the problems of high temperature, high altitude installation and debugging

technical paraneter:

Optional temperature range: -20C- -+60'C,- 30"C- -+70C,

-40C-+ 80C, .

extreme envi ronment :

0'C-+ 120"C (Lmtork split

actuator can be used)

relative humidity: 95% ( 70C )

(Customizable)

alti tude:

Not. higher than

2000m (Customizable)

Protection level:

IP 68

Explosion proof grade:

EXd 1ICT4

Working mode of motor: S2 -15MINShort term working system ,Class F

insulation S5 -Intermittent periodic working system,Minimum load duration 10%,

The maximum working frequency is 1200 C / h

Connection standard:

JB2920/ IS05210 (Customizable )

Cable inlet: M25*1.5(Two) (The maximum number of cable inlets is

6) (Customizable)

Main electrical parameters: .

Power. Supply: three-phase 380 V

AC 50Hz

single-phase 220V AC

50Hz

( Other customizable)

Contact capacity:

250VAC 5A, 30VDC 5A

Connection number:. 47

Signal conductor section:

Less than or equal to 2.5

square mn power wire

sect ion:

≤2.5 square mm

Switch_ input: Input mode

Passive contact Voltage 24

VDC+/-20% electric current≤10MA, Pulse width is greater .

than 100 ms Photoelectric isolation With reverse voltage

protect ion

Switch output: 0utput mode Passive contact; capacity 250VAC 5A, 30

VDC 5A

Set point input: Range 4 -20MA

Position feedback. output: Range4-20MA Load

capaci ty≤5000hm,Linearity 0. 3% control:

Deadband 0. 1% - 9. 9% adjustable .

LMT/ LMTMSeries actuator performance data sheet and mechanical data

+Optional rlange F05,Fa05. F07. F12 and fa07 u8e base. The type of base required must be specified

+The equipeent com0s with solid coupling. Final sechining by the valve sunufacturer is required.

*The optional supply voltage of the equipeent is AC380V, AC220V, 0ther voltages are customized.

LMT/ LMTM Series actuator performance data sheet and mechanical data

*Optional flange F05. Fa05. F07。 F12 and fa07 use base. The type of base required must be specified.

*The equipaent comes with solid coupling. Final machining by the valve anufacturer is required

*The optional pover supply voltage of the equipnent is AC380V and AC220V. other voltages are custonized.

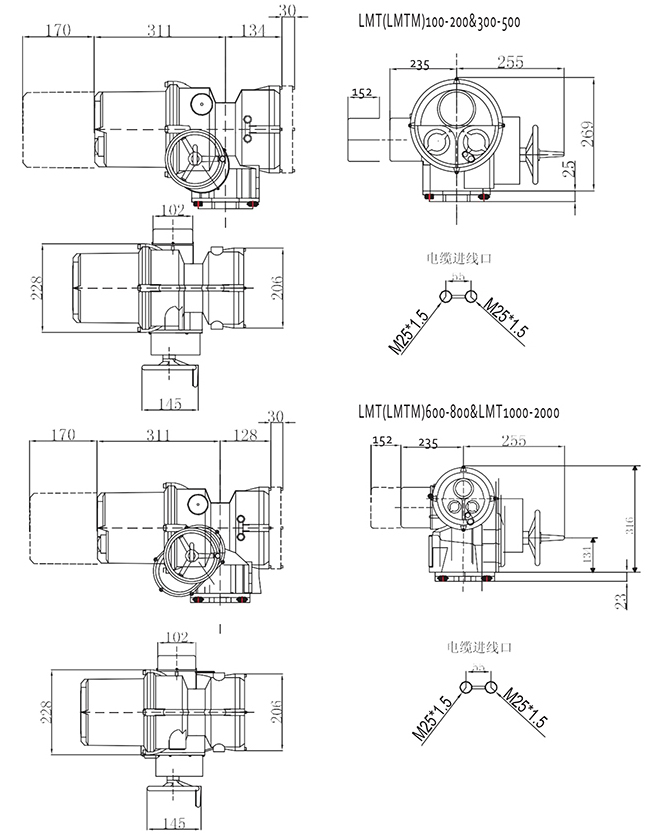

*LMTInstallation dimension of angul ar stroke actuator

LMT(1M)00-208300-500External dimension of actuator

MTORK Working principle diagram

*LMTORK Control and wiring

*Control and wiring

characteristics of the actuator. The funct ional characteristics of the actuator are connected. The funct ions

and corresponding terminals of the actuator are as follors:

The terminals used below are the terminals of basic configuration, and the other terninals are addit ional

contacts and al ternat ive funct ions.

*LMTORK Control and wiring

Switch type internal power supply wiring diagram

Wiring diagran of regu lating internal power supply

Mote: when selecting internal power supply,

No.4 is DC24 negative and No.5 is DC24

moaitive. wi ri n。di ncrom of

Note: only one type of power supply can bg, selected when selecting power supply mode, such as

Welcome to our website. If you have any requests or suggestions,please feel free to email us at vsdeme@vsdeme.com or use the following enquiry form. Please allow us to provide you with the best service.